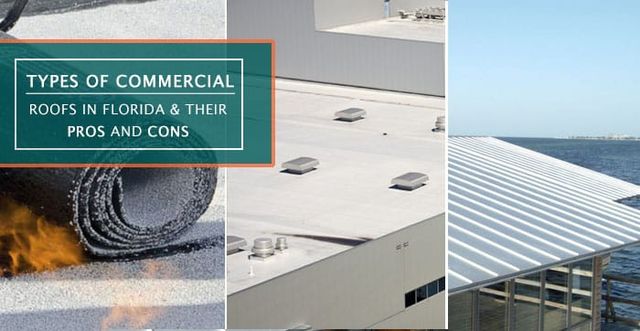

Review Of Rubber Torch Down Roof

It s reliable and robust.

Review of rubber torch down roof. Very informative i ve experienced the same issue since 2009 and everything in the article was right on point i m getting a new roof on 09 10 2020. Rubber roof installation on flat roofs. Designed for torch down roof application by pro roof contractors gaf tri ply app smooth is a strong resilient membrane that is suitable for new or reroofing projects as well as for use as flashing. This roof is over 25 years old.

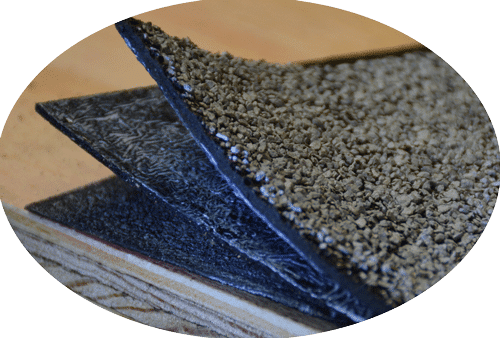

Torch down roofing is a type of roofing material that has been designed for low angle or flat roofs. Torch on felt roofing simply describes the method in which the material is applied. The membrane is composed of various types of modifiers reinforcements and surface treatments. This 25 year old 2 ply modified bitumen torch down rubber roof coated with aluminum asphalt paint which is meant to protect the surface against harmful uv rays it has had many years of scattered debris foot traffic from a rooftop a c and ventilation units being serviced yet there is no indication that repairs have ever been needed.

Installing a rubber roof on new construction is always the easiest and cleanest option. Torch down roofing with modified bitumen. Typical installations use a three layer system. A rubber roof left unprotected.

Torch down roofs are composed of two or more layers of a modified asphalt membrane applied with an open flame torch. Discover the various components of a torch down roof and the materials used to manufacture it. In the late 1970 s and first manufactured in the u s. This video is about installing a torch down rubber roof over tar and gravel.

Review of repairing a torch down rubber roof. While it can last up to 20 years installing torch down roofing can be a dangerous process and as such tends to cost more than traditional roofing materials. Plus learn the advantages and disadvantages of a torch down roof system. Notice the wrinkling and unevenness of the membrane.

Fix my rubber roof. Perforated underlay a 2mm underlay layer then 4 5mm felt. Modified bitumen mb torch down roofing membranes were first developed in europe in the mid 1960 s introduced in the u s. The membrane is available with a smooth surface.

Review of when not to repair an epdm rubber roof. This was exactly the info i was looking for. This membrane contains a core of nonwoven polyester mat that resists splits and tears. Ruberoid torch smooth membrane is backed by gaf a company with over 130 years in the roofing business.

Modern torch on felt roof. Coated modified bitumen rubber roof. A torch down rubber roof with silver coating for protection against ultraviolets. Its core is a strong resilient non woven polyester mat that is coated with weather resistant app polymer modified asphalt.