Resistance Of A 3 Micron Thick Sheet Of Copper

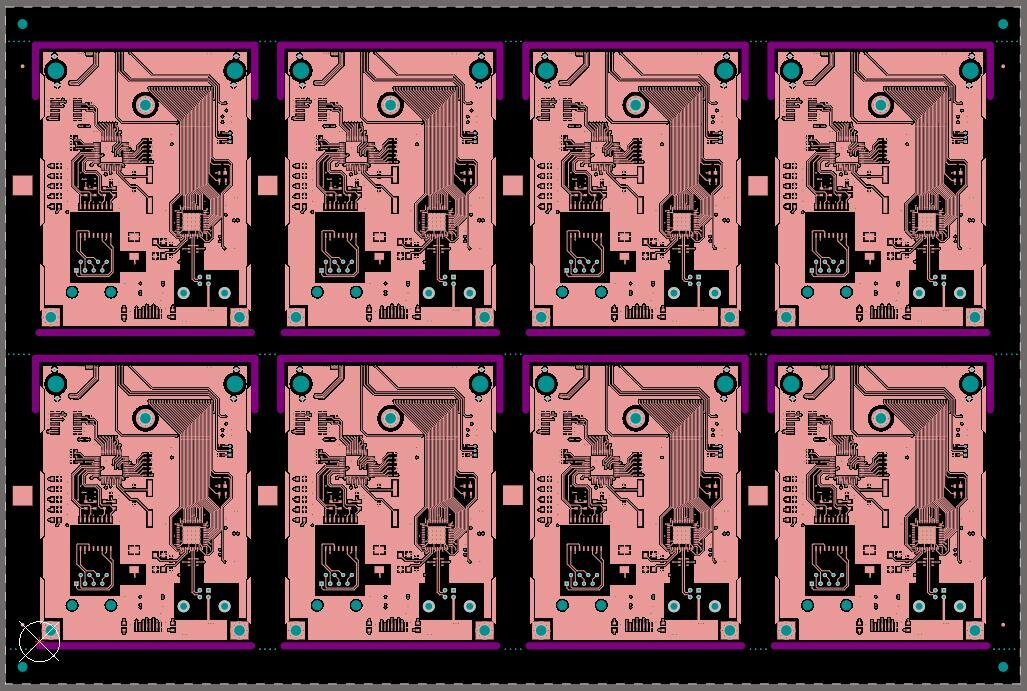

When specifying the thickness of copper on printed circuit boards pcbs the usual metric is ounces.

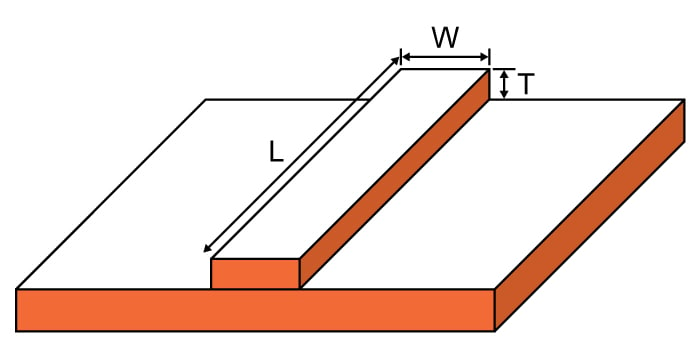

Resistance of a 3 micron thick sheet of copper. C1100 c1020 c1220 2 chemical composition c1100. This is oz on each side. If that trace is 1 2 ounce copper the dc resistance would be 1000 squares x 1 0. It is commonly used to characterize materials made by semiconductor doping metal deposition resistive paste printing and glass coating examples of these processes are.

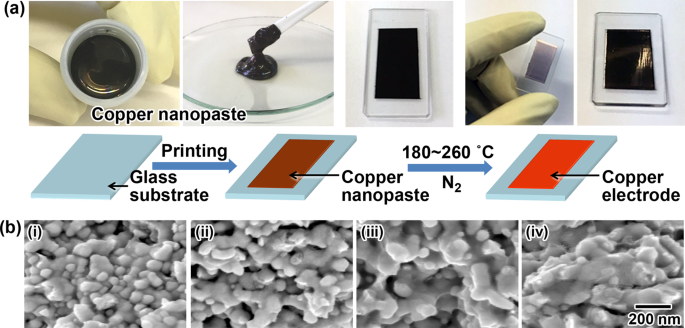

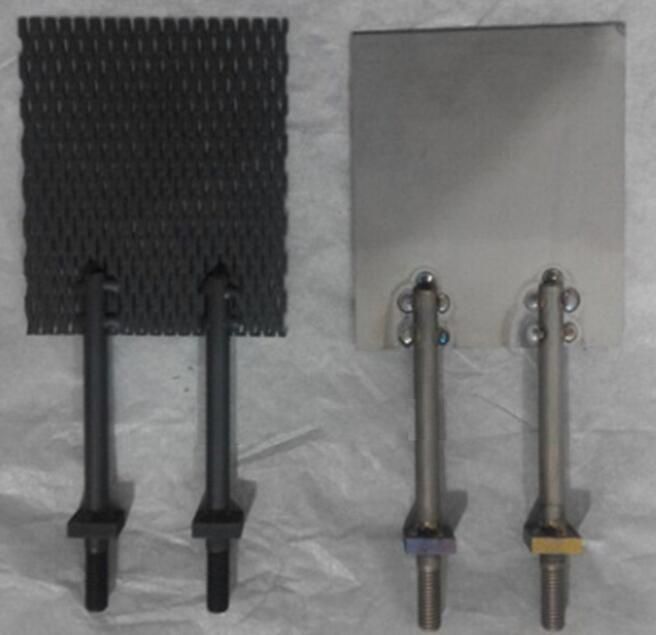

Doped semiconductor regions e g silicon or polysilicon and the resistors that are screen. Because the production panels are completely covered with copper the excess copper needs to be removed to reveal your design. And the anode positive electrode is usually either a block. If your target finished copper thickness is 1 oz we ll start with a oz sheet of material.

To do this a 1 1 size image of your design is photo plotted onto a film. Recommend seal hard anodize in 5 dichromate solution where increased corrosion resistance is required. Because the production panels are completely covered with copper the excess copper needs to be removed to reveal your design. Where extreme abrasion resistance is required do not seal as some softening will result.

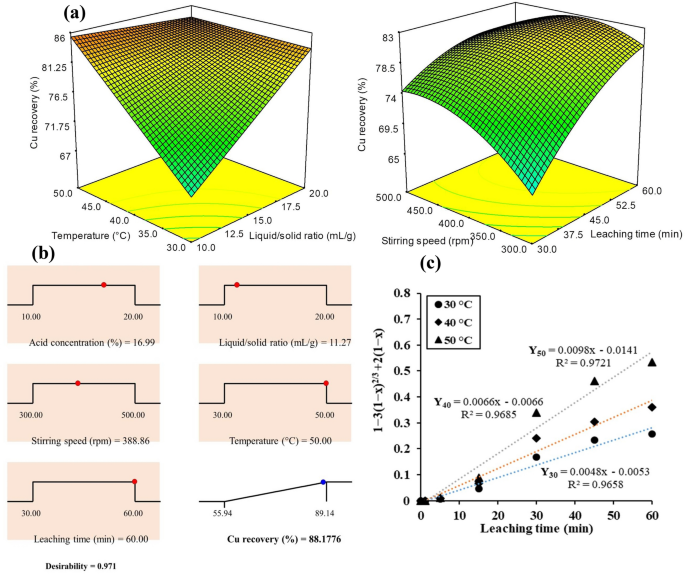

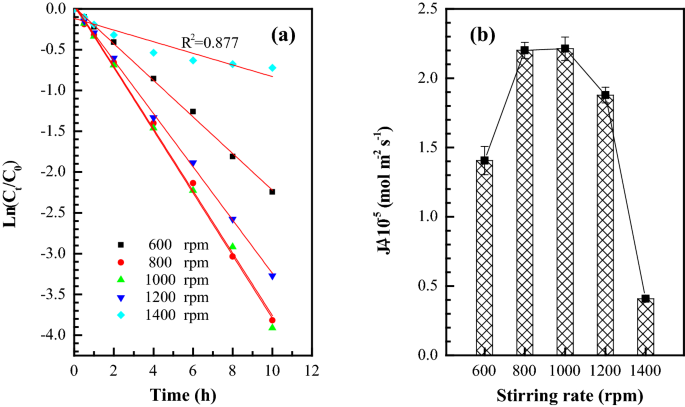

Below is a quick guide to help you determine which thickness best suits the needs of your project. If your target finished copper thickness is 1 oz we ll start with a oz sheet of material. P 0 015 0 04 3 oxygen content c1100. Sheet resistance often called sheet resistivity is a measure of resistance of thin films that are nominally uniform in thickness.

To do this a 1 1 size image of your design is photo plotted onto a film. O 1 4h 1 2h h o. Specifications of copper foil. Copper sheeting comes in thicknesses ranging from very thin copper foil to thick copper plate.

Corrosion resistance is good. Electroplating is a general name for processes that create a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current the part to be coated acts as the cathode negative electrode of an electrolytic cell. H hv gt 100 5 electric. Thick coatings over 004 will tend to break sharp edges.

The electrolyte is a solution of a salt of the metal to be coated. 5 micron copper foil. The unit of measurement used to identify the thickness of a sheet of copper varies e g gauge mil ounces per square foot inches millimeters. Thickness 002 to 0005 typical or as specified on drawing.

This is oz on each side. As part of our commitment to delivering the highest quality graphene at affordable prices our in house substrate processing results in copper grain sizes that are tens of square centimeters in area. This is the standard starting copper thickness on the external layers for pcbs with the 3 oz finished copper weight selection. Our 25 micron thick copper foil is sourced from a reliable quality assured supplier in the united states.